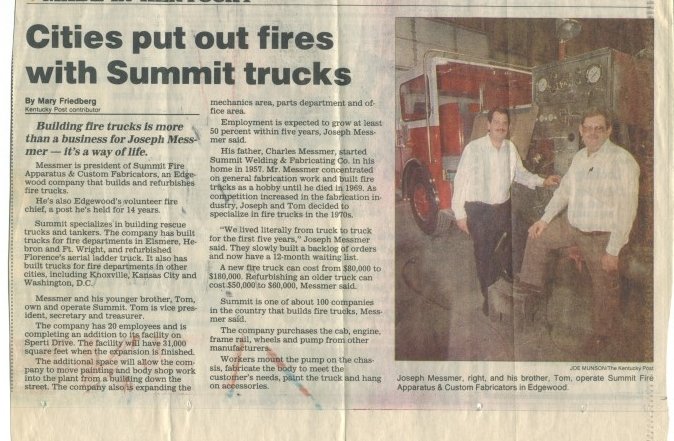

Our Company

Family Owned and Operated Since 1957

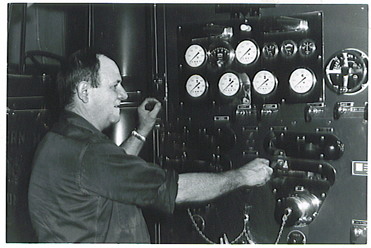

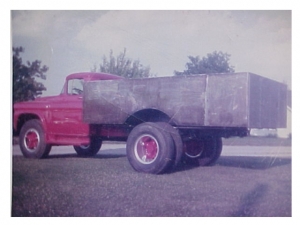

Charles Messmer started the company under the name of Summit Welding and Fabricating in 1957.Using his experience in fabricating and being a founding father and fire chief of the local fire department, Charles constructed the first fire unit, a Tanker, later that same year.

Two of Charles’s sons immediately followed in their father’s footsteps and came to work at Summit after school. Joe and Tom Messmer began learning the trade of welding and fabricating from their father and assumed current ownership after Charlie’s passing in 1969.

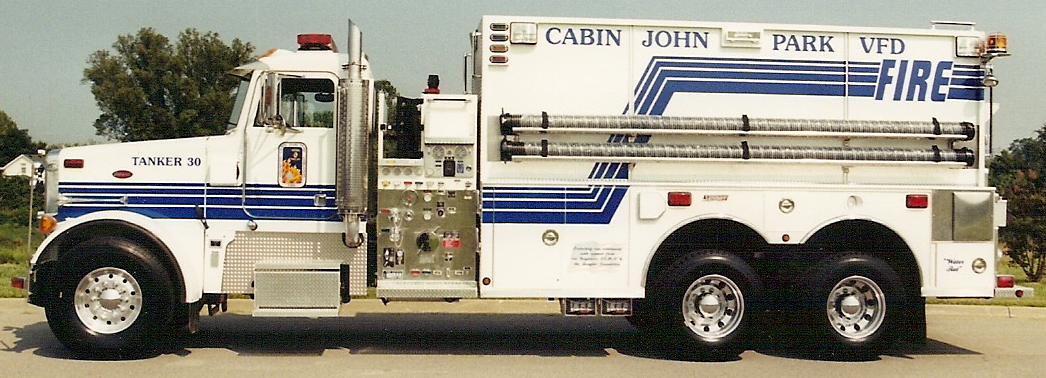

In 1975, Summit Welding and Fabricating became Summit Fire Apparatus with the emphasis as a refurbishment shop of fire apparatus. Over the years Summit and their employees gained experience and knowledge from repairing and refurbishing other manufacturer’s apparatus. Joe Messmer, President and Tom Messmer, Vice President had made the decision to change the mission of Summit Fire Apparatus from a refurbishment shop to apparatus manufacturer in 1980.

in 1994, Summit more than doubled its Edgewood, Kentucky plant from 14,500 sq. ft. to a 31,000 state of the art facility. Through computer aided technology and firefighter experienced management, Summit has developed a line of apparatus that includes Pumpers, Tankers, Rescue Trucks, Brush Trucks and specialty units such as our Haz-Mat Rescue and SCBA Refill Air & Light Vehicle.

Today, Summit Fire Apparatus continues its ·commitment to Quality at affordable Prices on every apparatus built.

Summit Brings Innovation to Air and Light

Summit Fire Apparatus remains family owned and operated and committed to providing quality apparatus. At Summit, we won’t try to put you in a cookie cutter truck. We pride ourselves on the fact that we can work within your budget without sacrificing innovative ideas. Our customers tell us what they need, and we make it happen.

In 2007 we added a new line of attack to the elements of fire and water with our air and light vehicle. Our SCBA breathing air and light vehicle is built on an International 4400 2-door. It has a 16′ Equipment body – 6 compartments and refill station, IH Engine 330 HP, exhaust brake retarder, Mako compressor, 100KV Marathon Electric Lima Mac generator. The Hale driveline transfer case is installed inside the frame rails. Our brushed stainless-steel operations panel is

located inside the fill and operations compartment. It includes all necessary controls and instruments for compressor and fill station operation. Other equipment includes SCBA cylinder sequencer, totally enclosed fragmentation station capable of charging 2 SCBA cylinders simultaneously while 2 others are attached and ready to revolve in, 28 bottle SCBA cylinder storage, Kussmaul pump plus super package. Lights include 2 Wilbur! Night Scan light towers, 8 GFE extend-a-lights, 2 Hannay 300′ Air hose reels, 2 Hannay 300′ electric reels and recessed into the body head rail, 3 1000-watt FRC Focus lights. The compartments have LED lights and ROM roll-up doors. Rud tire chains and a Weldon Brand rear vision camera complete the package.

We have been building quality, affordable custom fire trucks for over 50 years. Charles Messmer started the company with a 1957 Ford pick-up truck, a portable welder, determination and God-given talent. The company has changed and grown since then. But we hang onto the idea that listening to our customer is key. Our current line of apparatus includes Heavy Rescue Trucks, Mini-Rescues, Haz-Mat Units, Brush Trucks, Pumpers, Tankers/Tenders and Air & Light Vehicles. Our service department is available 24 hours a day. In addition to preventative maintenance, we do repair and collision work also refurbishment of older units.

After 50 years of manufacturing fire trucks and fighting fires, we have the expertise to build a safe and functional apparatus that will

serve your department for years to come

Let’s Talk Trash

Summit Fire Apparatus introduced the fire industry to an extended front bumper at FDIC 2001. We extended the front bumper 12″ and constructed boxes containing 2 hydraulic reels with pre-connected tools.

It must have been a great idea, we watched engineer after engineer photograph, sketch and measure our bumper. In part thanks to Summit Fire Apparatus’s innovation, front bumper extensions have become common place. Straight rescues with front bumper hose reels and tool storage have been showing up all over town. Any why not, it makes perfect sense to put the tools you need first up front, within easy reach and ready to use.

There is one component of our front bumper extension that our competitors still can’t seem to get right, the trash line. Our front bumper extension also has a quick attack 2″ front discharge or trash line with 50 to 200 feet of hose. That’s right, 2 hydraulic reels with pre-connected tools on one side of the front bumper and a trash line attached to as much hose as you need on the other side.

The front bumper is secured to the truck’s frame, no worries about the weight, and all compartment lids are water tight to protect your equipment.

Now Summit is raising the bar. We have added a 12,000 lb. winch with 125 feet of cable. The winch is accessed by simply removing the tools and lifting a hinged lid below the tool storage area. Let’s see them try to copy this!!

In 2007 Summit Fire Apparatus celebrated its 50th Anniversary. Our first piece of fire equipment, a tanker, was constructed in 1957 by Charles Messmer, company founder, then fire chief of the local fire department and the father of our current owners. The company remains family owned and operated and committed to providing quality, economy and innovation. Summit Fire Apparatus is truly a custom fire apparatus manufacturer, we build the units that the larger companies can’t or won’t. We have found that listening to our customer is key. With 50 years of manufacturing and firefighting experience we have the expertise to build a safe and functional apparatus that will serve your department for years to come.